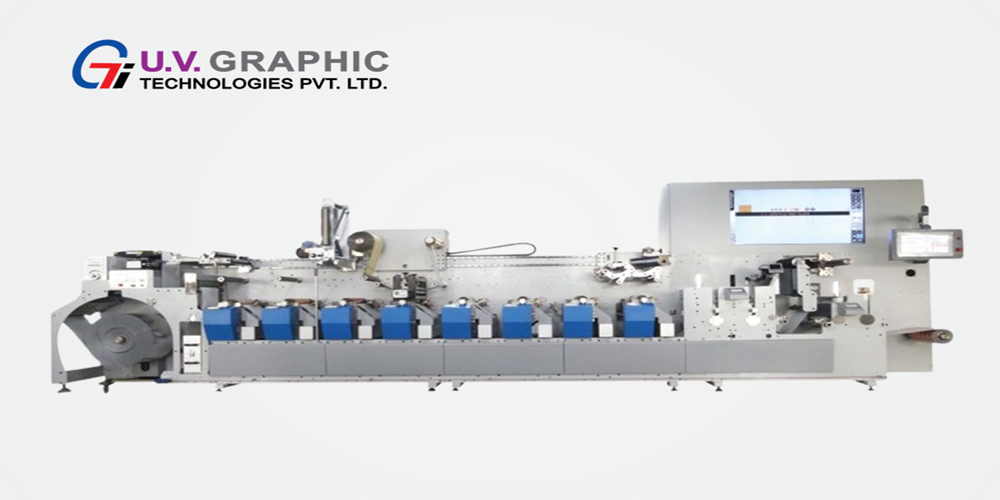

Any current printing and packaging business runs on innovations since it is the only viable way of staying relevant in the industry. Present-day businesses seek printing options that are quicker, cheaper, more adaptable, and friendly to the environment. In the development of the printing industries, especially the flexographic print A flexo printing machine, or flexo printer is fast enhancing the efficiency and versatility of various industries. This revolution is made possible by the flexo printing machines manufacturer, the gallant designer who is as technologically advanced as this revolution.

This blog is about flexo printing machines, where they are used, what technologies have been employed in their development, and what purpose a suitable manufacturer may serve in meeting the need for printing.

Reasons For Adopting Flexo Printing

Flexo Printing is a direct rotary printing technique whereby an image is printed onto flexible substrates using altered surfaces. Its undoubted strengths make it the most preferred of all the available technologies mainly where printing is large and abnormal situations exist.

Prime Features:

Flexibility: Able to print on paper, plastic films, foils or corrugated boxes of any sort.

High Speed: Very fast printing speed possible without harming print quality.

Low Cost: Short change-over time and low-cost printing cylinders.

Environmentally Friendly: Utilize water-based or uv inks hence minimizing pollution.

Personalization: Perfect for custom-made products like custom boxes or labels.

The Task of the Manufacturer of the Flexo Printing Machines

Flexographic printing’s effectiveness is reliant on the capacity of the manufacturer to design and fabricate efficient devices. Equipment suppliers are charged with the responsibility of incorporating the latest technology, addressing the machine’s lifespan, and offering solutions that cut across various industries.

1. Technological Innovation

2. Customization Capabilities

3. Focus on Sustainability

4. Quality Assurance

5. Global Reach

The Task of the Manufacturer of the Flexo Printing Machines

Flexographic printing’s effectiveness is reliant on the capacity of the manufacturer to design and fabricate efficient devices. Equipment suppliers are charged with the responsibility of incorporating the latest technology, addressing the machine’s lifespan, and offering solutions that cut across various industries.

Types of Flexo Printing Machines

Flexo printing machines are made of different designs and are intended for different uses.

1. Central Impression (CI) Flexo Press

2. Stack-Type Flexo Press

3. Inline Flexo Press

4. Wide-Web and Narrow-Web Flexo Machines

Applications of Flexo Printing Machines

The flexo printing machines can be used in many sectors for many different reasons, such as using different materials and moieties to produce several things in different scales.

1. Packaging

2. Labels

3. Corrugated Boxes

4. Flexible Films

5. Stationery and Paper Products

6. Specialty Printing

Innovations in Flexo Printing Technology

Technological advancements have enhanced the efficiency, accuracy, and eco-friendliness of flexo printing machines.

1. AI and Automation

2. Hybrid Printing

3. Sustainable Inks

4. High-Resolution Printing

5. IoT and Data Analytics

6. Compact Designs

Choosing the Right Flexo Printing Machines Manufacturer

Investing in the right manufacturer ensures long-term efficiency, quality, and cost savings. Here’s what to consider:

1. Experience and Expertise: Established manufacturers with a history of delivering reliable machines.

2. Innovation and R&D: A focus on research and development ensures cutting-edge technology.

3. Customization Options: Manufacturers offering tailored solutions are better equipped to meet unique business needs.

4. Sustainability Practices: Look for manufacturers prioritizing eco-friendly designs and processes.

5. After-Sales Support: Comprehensive training, maintenance, and spare parts availability.

Conclusion

Flexo printing machines have transformed the printing and packaging industry, offering unmatched speed, versatility, and quality. Choosing a reliable flexo printing machine manufacturer ensures you stay ahead in the competitive market. Whether you're in packaging, labeling, or specialty printing, investing in the right technology and partner can elevate your business to new heights.